Notes

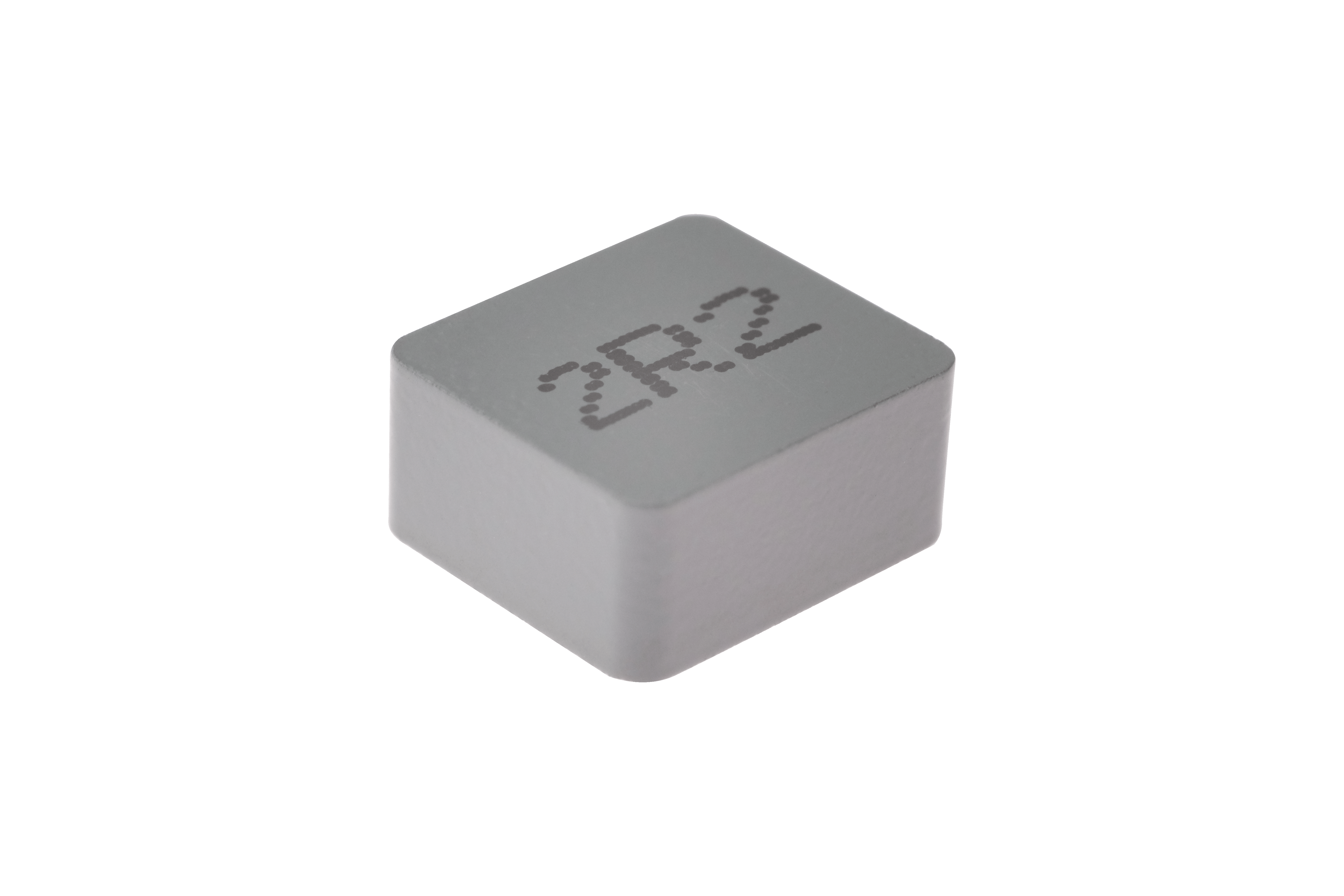

All data is based on testing at an ambient temperature of 25 ℃.

The inductance test conditions are 1kHz and 1V.

Saturation current: The actual DC current value loaded when the inductance value drops by 20% of its initial value.

Temperature rise current: causes the product temperature to rise to Δ The actual DC current value loaded at T40 ℃ (Ta=25 ℃).

Special reminder: Circuit design, component layout, printed circuit board (PCB) size and thickness, and heat dissipation system can all affect product temperature.

Please be sure to verify the product's heating condition during final application.

Save

Storage conditions for products in packaging: temperature 5-40 ° C, relative humidity less than or equal to 70%.

If taken out for use, the remaining products should be sealed with plastic bags and stored according to the above conditions to avoid terminal (electrode) oxidation and affecting the welding status.

The storage period of the product is not recommended to exceed 12 months. Under other influences, the terminals may deteriorate, leading to poor solderability.

Please do not store the product in an unsuitable environment with high temperature, humidity, dust, or corrosive gases.

Please handle with care to avoid damage caused by product falling or improper use.

The grease on your hands can lead to a decrease in solderability, and direct contact with terminals should be avoided.