PFC Inductor

PFC (Power Factor Correction) significantly improves the power factor in a circuit, reducing the reactive power and increasing the efficiency of power conversion. In 2022, the penetration rate of electric vehicles (EVs) in the passenger car market reached 27.6%, showing a 12.6% increase compared to the previous year. It is projected to further increase to 36% in 2023.

With the continuous growth in the number of new energy vehicles, there is a persistent and strong demand in the market for charging stations. The current ratio of vehicles to charging stations is 3:1, indicating the potential for accelerated development in this sector. High-power applications in new energy, photovoltaic systems, energy storage, and inverters are widely utilized.

1.Adoption of high-saturation, high-Curie temperature, low-loss magnetic materials, allowing for operation in a wide temperature range of -40°C to 155°C and enabling higher power density.

2.Utilization of a high-temperature and high-voltage resistant flat copper wire winding structure, resulting in lower capacitance, higher current density, and improved reliability

3.Implementation of magnetic simulation and structural simulation techniques to provide optimization suggestions for customers and jointly develop high-efficiency and high-reliability products.

4.Utilization of in-house developed equipment for semi-automated winding, assembly, and potting processes, ensuring higher product consistency.

5.Compliance with RoHS and REACH regulations, meeting AEC-Q200 certification requirements.

6.Customized components tailored to meet specific customer requirements, ensuring a perfect match.

Widely applied in On-Board Chargers (OBCs), charging stations, high-power new energy systems, photovoltaics, energy storage, and inverters.

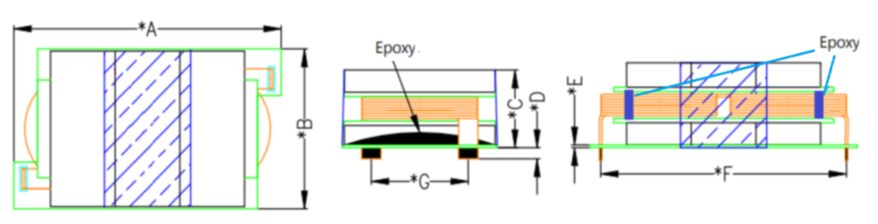

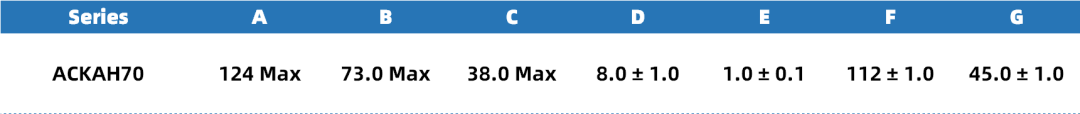

unit:mm

Achieved mass production.

Remark:

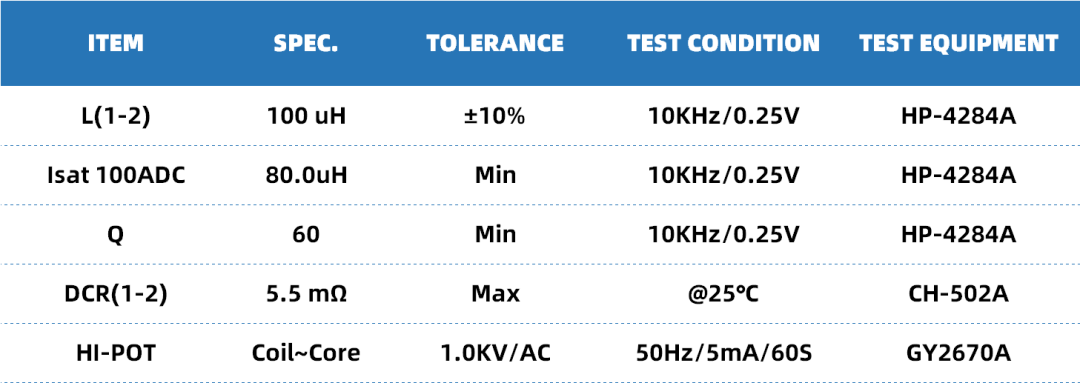

1. All test data is reference to 25℃ ambient.

2. Test Condition:As shown in the table

3. L,Q,DCR,HI-POT,TR is full-test before shipment, Isat is sampling test.

4. Operat between temperature range -40℃ to +155℃(Including self - temperature rise)

5. Storage Temperature : -40℃ to +125°C

6. Application voltage ≤380VAC